3D Prototyping and Manufacturing Services

Powering your ideas with 3Deck by studio juanita’s

Empower your industrial vision with 3Deck. We specialize in printing high-quality 3D parts and products for industrial applications. From prototyping to manufacturing, we deliver exceptional results.

Our 3D printing capabilities

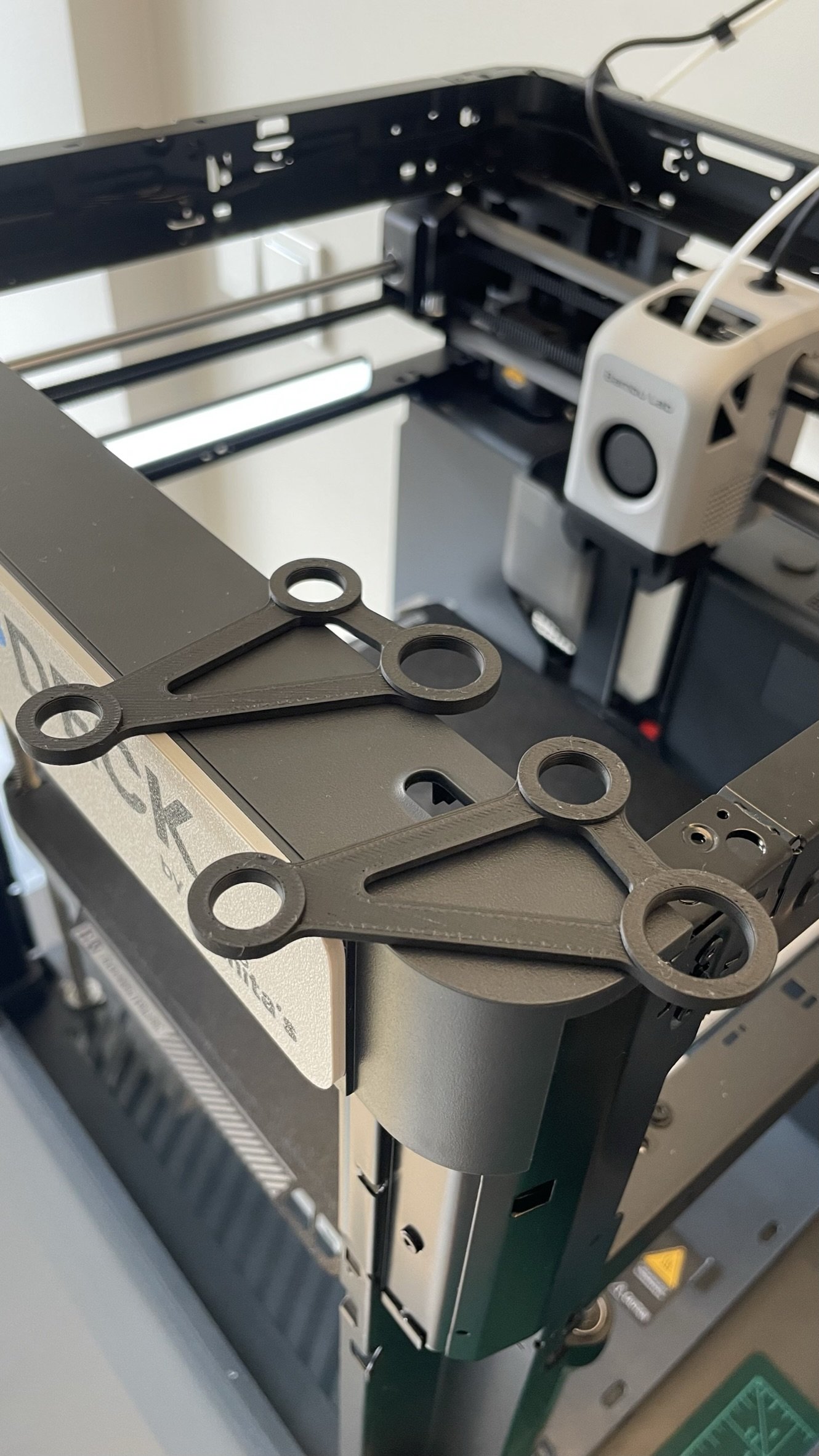

At 3Deck, we offer a robust lineup of 3D printing capabilities to meet your unique needs. With three FDM 3D printers at our disposal, we have the capacity to bring your designs to life with precision and efficiency.

Our versatile printers are ready to produce a wide range of parts and products, tailored to your specifications. From functional prototypes to intricate industrial components, we have you covered. Trust our expertise and cutting-edge equipment to deliver exceptional quality and timely results for your 3D printing projects.

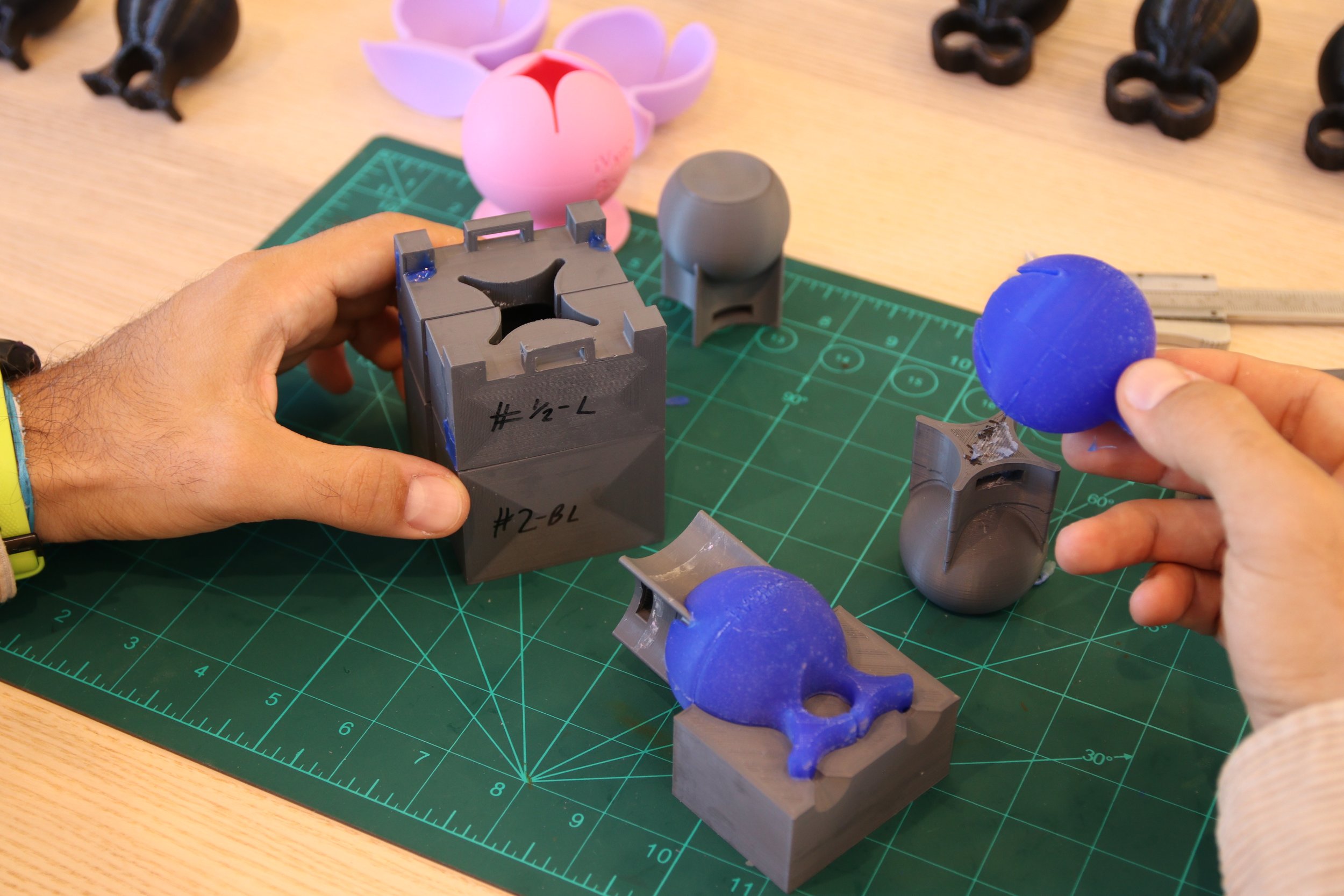

Efficient Mold Production

Industrial 3D printing enables the production of custom molds quickly and cost-effectively. By leveraging the design freedom and rapid turnaround times offered by 3D printing, manufacturers can create molds for casting processes, injection molding, or even rotational molding. This approach allows for efficient production of complex shapes and reduces the lead time typically associated with traditional mold manufacturing methods.

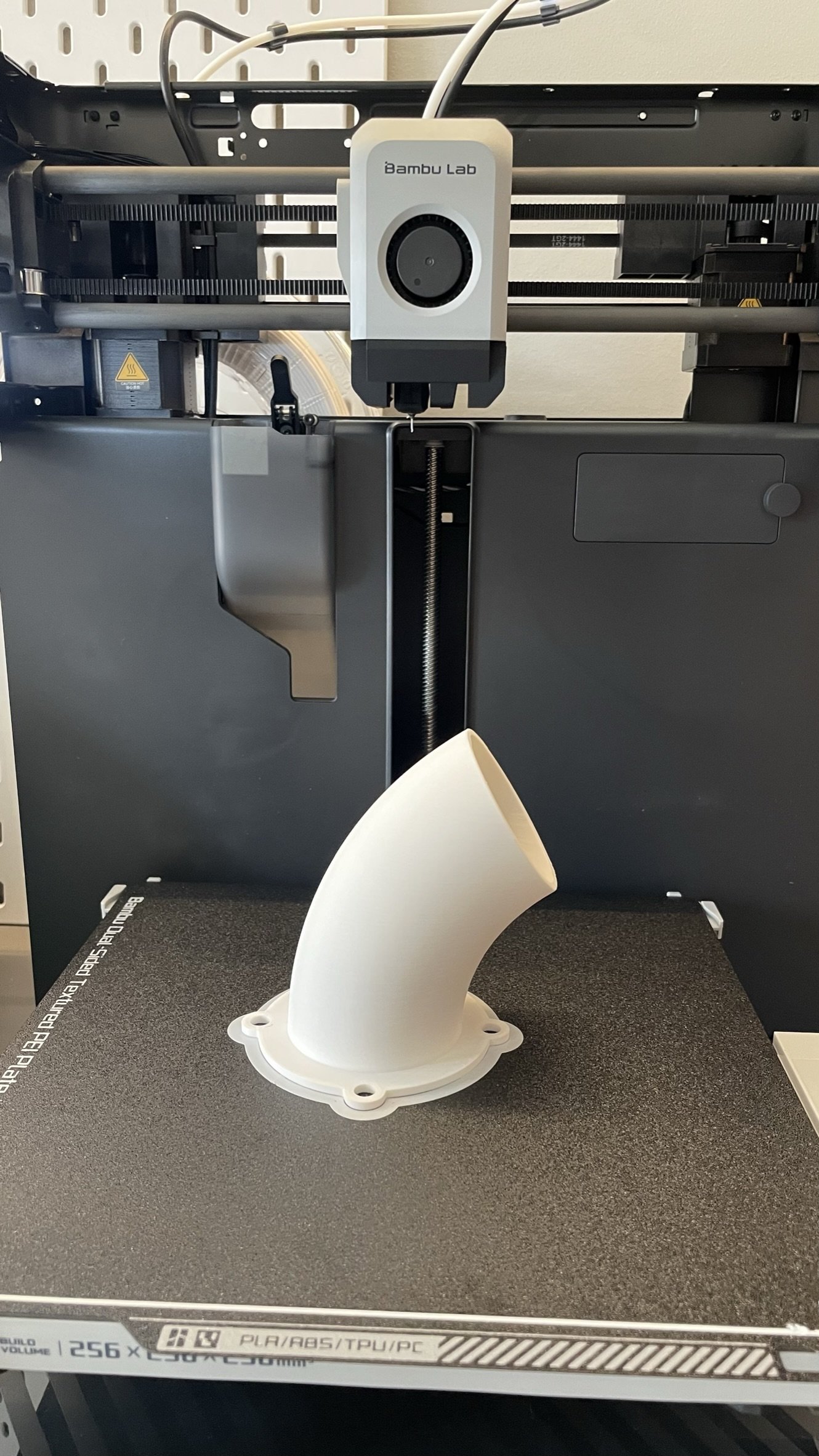

Accelerating Innovation

With industrial 3D printing, companies can rapidly fabricate functional prototypes for testing and validation purposes. This approach allows engineers and designers to iterate and refine their designs before committing to expensive tooling or mass production. By utilizing 3D printing technology, businesses can reduce development time, minimize costs, and ensure optimal performance of their products.

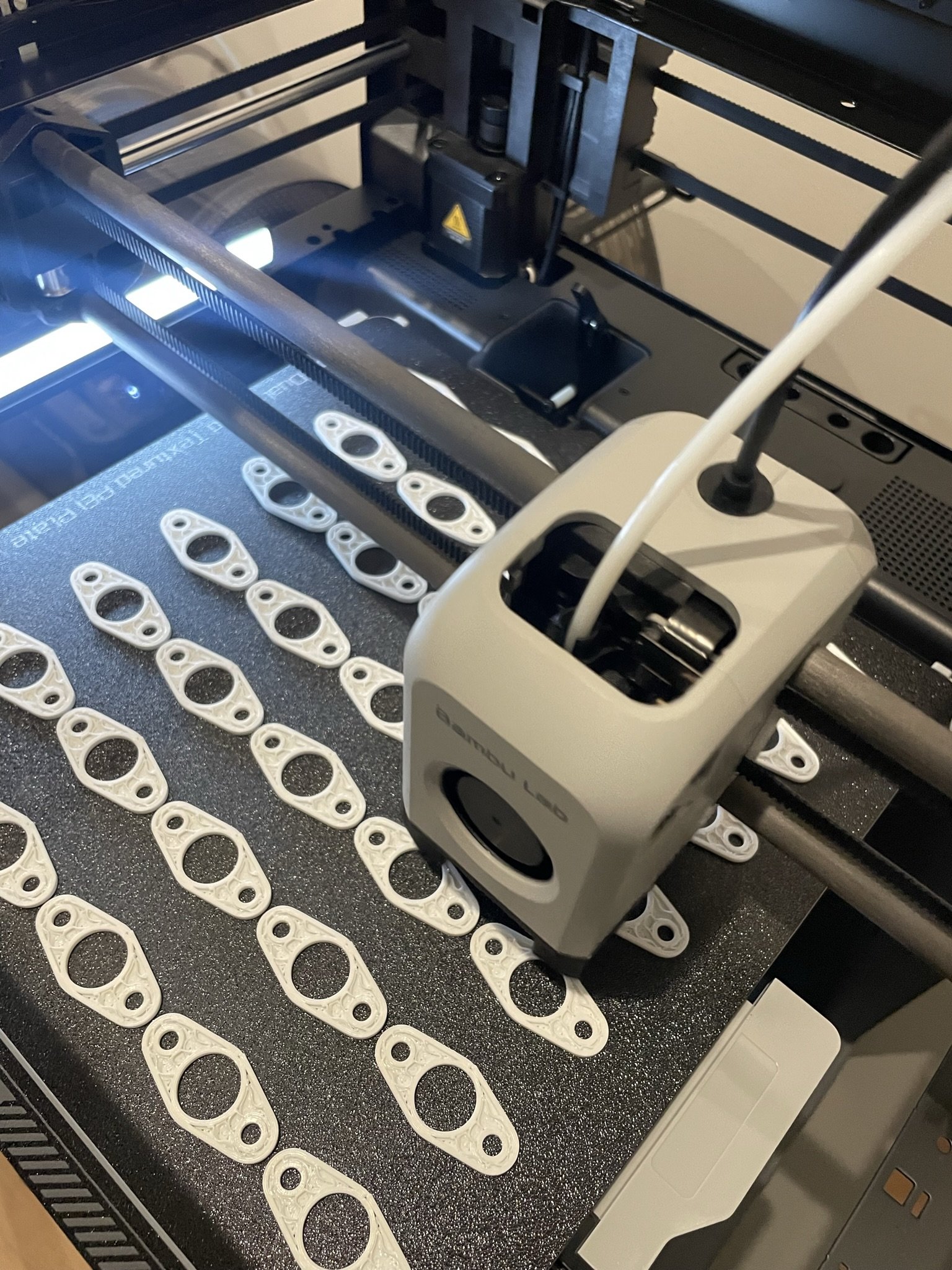

Cost-Effective Bulk Production

Industrial 3D printing can also be utilized for producing parts and components in bulk quantities. By leveraging high-capacity 3D printers and optimizing the manufacturing process, companies can achieve cost-efficient production runs without the need for traditional manufacturing tooling. This approach is particularly useful for low-volume production, customized products, or niche markets where the economies of scale are not viable.

Why FDM Printing?

Design Freedom

FDM allows for intricate and complex designs to be realized with ease. Its layer-by-layer deposition process enables the creation of parts with intricate geometries, internal features, and custom structures that are otherwise difficult to produce using traditional manufacturing methods.

Rapid Prototyping

FDM enables fast turnaround times, allowing for rapid iteration and design refinement. Engineers and designers can quickly produce functional prototypes for testing, validation, and gathering feedback. The ability to iterate rapidly helps accelerate the product development cycle and bring products to market faster.

Material Versatility

FDM supports a wide range of thermoplastic materials, including high-performance engineering plastics. This versatility allows for the production of functional prototypes and end-use parts with properties such as strength, flexibility, heat resistance, and chemical resistance. Industrial applications can benefit from using materials tailored to meet specific requirements.

Customization and Personalization

FDM empowers customization and personalization by enabling the production of unique parts with specific features or variations. This flexibility is beneficial for creating customized products or components tailored to individual customer needs.

Cost-Effectiveness

FDM offers cost advantages over traditional manufacturing techniques, particularly for low-volume production and complex geometries. With FDM, there is no need for expensive tooling or molds, which significantly reduces upfront costs. Additionally, FDM eliminates material waste by only using the necessary amount of filament, making it a more economical choice.

Manufacturing Complexity

FDM excels in manufacturing parts with internal channels, undercuts, and intricate geometries that are challenging or impossible to achieve with traditional methods. This capability expands the design possibilities, offering more opportunities for innovation and improved functionality.

Why choose us?

At 3Deck, we stand out as a young and dynamic team driven by a passion for innovation and excellence.

Fresh Perspective

We bring a fresh and innovative approach to every project, fueled by our passion for staying up-to-date with new technologies and trends. Our energy drives us to push boundaries and deliver exceptional results.

Technical Expertise

We possess deep industry understanding and extensive technical expertise. Our years of education, training, and hands-on experience enable us to provide cutting-edge solutions with professionalism and precision.

Collaborative Approach

We value collaboration and open communication, actively involving clients in the project development process. By understanding your goals, challenges, and vision, we tailor our services to meet your specific requirements and exceed expectations.

Personalized Solutions

We recognize that each client and project is unique. We take the time to listen, understand objectives, and offer personalized solutions. Whether it's 3D prototyping, product design, or manufacturing, we ensure effective and efficient results aligned with your goals.

Commitment to Quality

Quality is at the core of everything we do. We take pride in delivering exceptional results that meet the highest standards. From the initial concept to the final product, our strict quality control measures ensure excellence and reliability